| Standard Test | Each valve is factory tested with nitrogen at 1000 psig (69 bar) for leakage at the seat and packing, the maximum allowable leak rate of 0.1 sccm. |

|---|---|

| Optional Hydrostatic test | This test is performed with de ionised water at 1.5 time the working pressure. Other tests like vibration, temperatures, helium etc are available upon requests. |

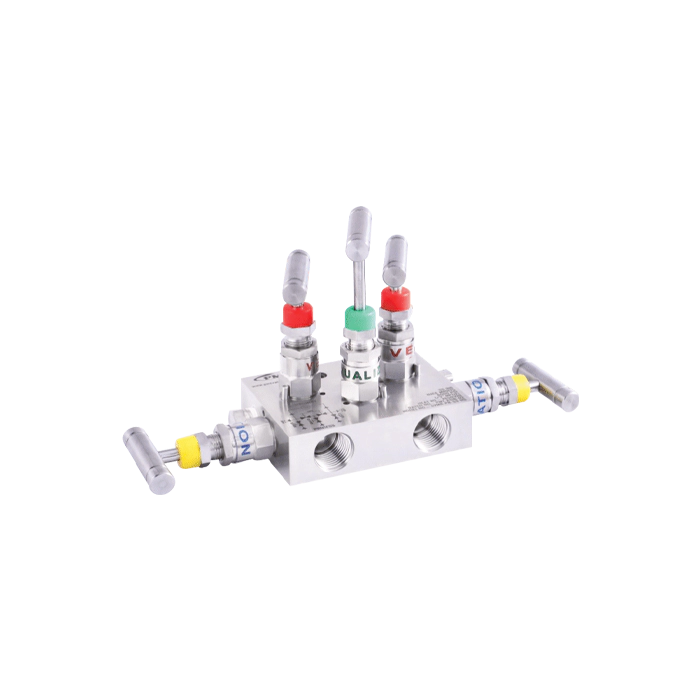

5 Way Valve Manifolds

A 5 Way valve manifold features five ports and is commonly used in more complex systems. It typically includes one inlet, one outlet, and three additional ports for various flow paths and functions. This configuration allows for more intricate control and distribution of fluid.

Applications: Often used in systems with multiple actuators or circuits requiring precise control over fluid distribution. Common in applications like pneumatic cylinders where fluid needs to be directed to different parts of the system or where multiple functions need to be controlled from a single manifold.

Advantages: Offers advanced control capabilities, enabling the management of multiple flow paths and functions within a single unit. This complexity supports sophisticated system designs and enhances operational efficiency.

.jpg)